A slab is a horizontal structure constructed with concrete, used in buildings or houses to construct ceilings, floors, roofs, or walls. The slab supports the different types of floor load by transferring it to the beams. The slab is a structure that generally used to have a thickness (depth) less than its breadth and length.

What is One-way slab?

Oneway slabs have loads in one direction only, and two beams from opposite sides give support from two sides. It bends in only one spanning direction. Usually, a long and narrow structure is best suitable for a oneway slab. The ratio of the longer span to the shorter span in one way slab is greater than two. For example, consider any structure of a balcony where it has reinforcement bars (Strong steel rods) in one direction that runs parallel to the shorter side.

Difference between oneway and two-way slab

- A one-way slab needs less steel; however, a two-way slab requires more steel for supporting bi-directional spanning.

- The major difference between a two-way slab and a oneway slab is that two slabs bend in two directions and get beam support from all sides, whereas a oneway slab is supported by beams from two opposite sides.

- The ratio of a longer span to a shorter span in a one-way slab is greater than two, but in a two-way slab, it is less than two.

- A one-way slab transfers the load to the opposite supporting beams, whereas two-way beams transfer the load within the walls.

Benefits of a oneway slab

- Oneway slabs are more economical compared to others. It is available on a low budget, as less steel is required.

- A one-way slab is a good fit for spans that have a distance between two supports of 3.6 meters.

- It goes well for any shortest direction due to its greater slab depth.

Usage of oneway slab

The one-way slab is best suited for narrow and long construction and does not work with any rectangular structures. The residential buildings, corridors, or any small rooms are the perfect structure for using the oneway slab.

Construction Tips of One-way Slab

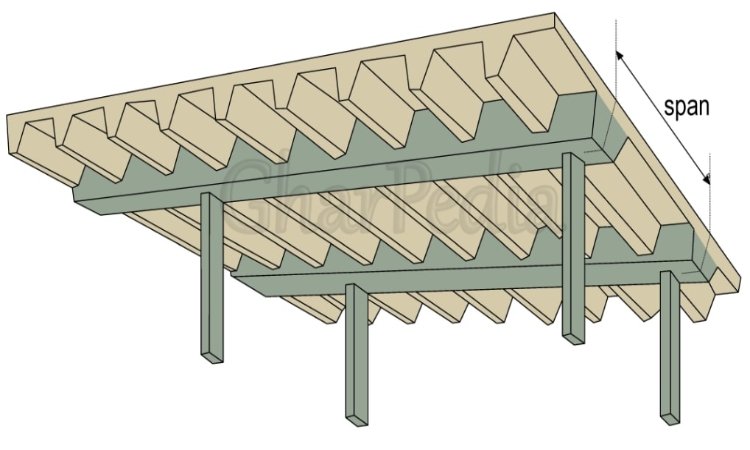

The first step of constructing one-way ribbed slab is to place formwork made up of steel or timber considering the correct shape and dimension. The steel reinforcement is placed within the formwork. Once the reinforcement is placed within the formwork, the concrete mortar is poured, covering all the areas of the slab. The concrete slab is left for hardening, which is called curing. After the slab gains enough compressive strength, the framework is removed, and the oneway slab is finally prepared.

Oneway slabs give the aesthetic look of lightweight slabs. It is best suitable for small-span buildings or structures. It is economical and perfect for any structure that does not require carrying a heavy load.

Frequently Asked Questions

What is the span ratio of one-way slab?

The span ratio of the longer span and shorter span of a oneway slab is always greater than two.

What is the minimum thickness of the one-way slab?

The minimum thickness should be within 4-10 inches.

What is the principal rule followed in one-way slab?

The loads are transferred in only one direction for one-way slab.